User:Christopher Thomas/Chris's CNC Tips: Difference between revisions

(→Numbers for cutting: Filled in section. Renamed section.) |

(Created section (depth per pass, step-over, maximum depth).) |

||

| Line 86: | Line 86: | ||

* ''FIXME: link to "Machinery's Handbook" goes here.'' | * ''FIXME: link to "Machinery's Handbook" goes here.'' | ||

* ''FIXME: link to a free feeds-and-speeds calculator goes here.'' | * ''FIXME: link to a free feeds-and-speeds calculator goes here.'' | ||

== Other numbers for cutting == | |||

When cutting a deep slot you normally make several passes rather than trying to cut the entire thickness at once. When hollowing out an area, not only will you make several passes, but the tool will move in a spiral pattern to hollow it out a small distance at a time. The numbers used for this are important, but there are easy ways to set them. | |||

=== Glossary === | |||

* '''Length of cut''' is the deepest you can cut into a material with a given tool. This is normally '''three times the tool diameter'''. | |||

** Some tools have a length of cut greater than this. If you need to cut deeper, you can use a tool like that. They're harder to find, and normally top out at four times the tool diameter. | |||

** If you're cutting a staircase pattern, you can cut deeper - this is just the maximum depth of each stair-step. Be careful that you don't run the machine's spindle into the higher parts of the shape, though. | |||

** If you try to cut deeper than the "length of cut", '''bad things happen'''. The tool's shank rubs against the material, so it won't cut, the machine may lose track of where it is (it thinks it's moving but it isn't), and the tool and material both heat up a lot. This will probably ruin your work and may even damage the cutting tool. | |||

* '''Depth per pass''' is how deep each cutting pass is relative to the previous pass. This is normally '''equal to the tool diameter'''. | |||

** For very soft materials, like balsa wood or foam, you can cut twice as deep. For very hard materials, you might want to only cut half as deep. | |||

** If you cut too deep in one pass, there are large sideways forces on your tool and on the machine. This can cause the machine to lose track of where it is (it thinks it's moving but it isn't), or can nudge your workpiece out of position, or can cause the tool to deflect out of position (for not-very-rigid machines), or can even break the cutting tool. | |||

* '''Step-over''' is how far apart sideways different passes are when hollowing out an area. This is normally '''half the tool diameter'''. | |||

** Setting this larger leaves a worse finish, but can be useful for "roughing" (removing lots of material quickly) in soft materials. | |||

** If you step over by too large an amount, there are larger sideways forces on your tool and on your machine. This is usually not enough to be dangerous, but you might want to reduce depth per pass to compensate. | |||

** Fusion 360 sets step-over to 0.9 times the tool diameter, which leaves a poor finish and can cause large forces in hard materials. | |||

=== Summary === | |||

* Don't cut deeper than three times the tool diameter (under most conditions). | |||

* Depth per pass should be set equal to the tool diameter. | |||

* Step-over should be set to half the tool diameter. | |||

Revision as of 20:51, 3 November 2019

This document collects Chris's rules-of-thumb for doing CNC work.

You can break these rules, but knowing when and how to do so takes experience. The idea is that if you do follow these rules, you should be able to get consistently good results as a beginner.

Tools to use

Glossary

- A CNC router is used for cutting soft materials like wood or plastic. It has a high spindle speed (usually 12,000-20,000 RPM).

- A solidly-built CNC router can machine soft metals like aluminum or brass, but aluminum will need coolant and due to high RPM you may need carbide tools. A CNC router that is not solidly built will do a bad job and might even be damaged if used to machine metal.

- FIXME: Links to the shop's routers go here.

- A CNC mill ("milling machine") is used for cutting hard materials like metal (aluminum, brass, steel). It has a lower spindle speed (usually 4,500 RPM or lower) and is built like a tank. The area being cut needs to be sprayed with coolant (unless cutting brass).

- A CNC mill can be used with soft materials like wood or plastic, but due to the low spindle speed, the quality of the cut may be poor.

- FIXME: Link to the almost-a-mill goes here.

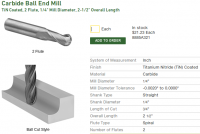

- An end mill is a cutting tool used with CNC mills and routers.

- You want a "center-cutting" end mill with "spiral flutes" in the "up-cutting" direction. Two flutes is a good number for most materials.

- For the FIXME: name of small router router, the end mill needs a 1/4" shank.

- End mills are made from "high-speed steel" or from "carbide".

- Carbide can cut at higher RPM but is more expensive and easier to damage (it'll chip if dropped on a table). It's a good idea to use it when cutting metal, and it's needed when cutting steel.

- High-speed steel is less expensive and works fine for wood and plastic. It can be used with soft metals like aluminum and brass, but will wear out more quickly with them. They often have coatings (titanium nitride or other) to make them last longer.

- A square end mill has a flat bottom. It's used when you want to leave a flat surface with vertical walls. A ball end mill has a rounded bottom. It's used when carving 3d surfaces.

- You want a "center-cutting" end mill with "spiral flutes" in the "up-cutting" direction. Two flutes is a good number for most materials.

Summary

- If you're cutting wood or plastic, use a router. If you're cutting metal, use a mill if you can.

- If you're cutting a complicated 3d surface, use a ball-end mill as the cutting tool. Otherwise, use a square-end mill.

Links for buying

- 1/4" shank:

"Feeds and Speeds" for cutting

Machining works a lot like whittling - the end mill is shaving off thin slices of material as it advances through the workpiece. How fast the cutting edge moves through the material and how thick the slices are matters; these are controlled by setting several numbers that describe how the cut happens.

Glossary

The two values that you can set are:

- Speed is how fast the spindle is turning. This is given in revolutions per minute (RPM).

- This is limited by your machine. For a decent router, it's variable from 12,000 to 20,000 RPM. For a hobby router, it's usually fixed at 12,000 RPM. For a decent mill, it's variable up to 4,500 RPM, with pulley belts that get changed for every factor of 2 speed difference. For a hobby mill, it's either fixed-speed for each belt or runs at only one speed.

- Feed rate is how fast the cutting tool is moving through the material. This is given in inches per minute or millimeters per minute.

- To convert between imperial and metric, use 100 mm/min = 4 in/min.

- The rapid rate is how fast the tool moves when it's not inside the material. This defaults to a high value (1000 mm/min or 40 in/min or more).

- The feed rate is how fast the tool moves sideways through the material. It's set depending on the material.

- The plunge rate is how fast the tool moves vertically through the material. Set it to a quarter the feed rate.

- The ramp rate is how fast the tool moves down and sideways through the material. Set it equal to the plunge rate.

The derived values you're actually trying to set are:

- Surface feet per minute is how fast the flutes on the cutting tool are moving when they shave off a piece of the material.

- This should stay more or less the same for a given material no matter what size of tool you use.

- Tools with larger diameter need lower RPM, and tools with narrower diameter need higher RPM, to keep SFM constant.

- If you can't change the RPM, then for a given material, only a few sizes of tool will work well. Others will either heat up too much (RPM and SFM too high) or will leave a poor-quality cut (RPM and SFM too low).

- Chip load is how thick the slices being shaved off the material are.

- This should stay more or less the same for a given material.

- Tools with more flutes need a higher feed rate, as they're shaving off more slices per revolution.

- Tools with higher RPM need a higher feed rate, as they're shaving off more slices per minute.

- There are limits to this - a very small tool at very high RPM still can't advance too quickly without breaking the tool. So, you're stuck shaving thinner slices under these conditions.

- The practical upshot is that a 1-flute tool should have half the feed rate of a 2-flute tool, and a 4-flute tool can have twice the feed rate of a 2-flute tool.

Summary

- For a given tool size and material, there's a "sweet spot" RPM value that works well.

- For fixed RPM machines, this means there are only a few tool sizes that will work well for a given material.

- You can spin faster if you have carbide tools, but spinning too slow leaves a worse cut.

- For a given RPM and number of flutes, there's a "sweet spot" feed rate that works well.

- With twice as many flutes, feed at twice the rate. With half as many, feed at half the rate.

- You have to look up these numbers instead of calculating them (calculations don't work very well).

Useful links

- FIXME: link to each machine's wiki page of feeds and speeds goes here.

- FIXME: link to "G-Wizard" goes here.

- FIXME: link to "Machinery's Handbook" goes here.

- FIXME: link to a free feeds-and-speeds calculator goes here.

Other numbers for cutting

When cutting a deep slot you normally make several passes rather than trying to cut the entire thickness at once. When hollowing out an area, not only will you make several passes, but the tool will move in a spiral pattern to hollow it out a small distance at a time. The numbers used for this are important, but there are easy ways to set them.

Glossary

- Length of cut is the deepest you can cut into a material with a given tool. This is normally three times the tool diameter.

- Some tools have a length of cut greater than this. If you need to cut deeper, you can use a tool like that. They're harder to find, and normally top out at four times the tool diameter.

- If you're cutting a staircase pattern, you can cut deeper - this is just the maximum depth of each stair-step. Be careful that you don't run the machine's spindle into the higher parts of the shape, though.

- If you try to cut deeper than the "length of cut", bad things happen. The tool's shank rubs against the material, so it won't cut, the machine may lose track of where it is (it thinks it's moving but it isn't), and the tool and material both heat up a lot. This will probably ruin your work and may even damage the cutting tool.

- Depth per pass is how deep each cutting pass is relative to the previous pass. This is normally equal to the tool diameter.

- For very soft materials, like balsa wood or foam, you can cut twice as deep. For very hard materials, you might want to only cut half as deep.

- If you cut too deep in one pass, there are large sideways forces on your tool and on the machine. This can cause the machine to lose track of where it is (it thinks it's moving but it isn't), or can nudge your workpiece out of position, or can cause the tool to deflect out of position (for not-very-rigid machines), or can even break the cutting tool.

- Step-over is how far apart sideways different passes are when hollowing out an area. This is normally half the tool diameter.

- Setting this larger leaves a worse finish, but can be useful for "roughing" (removing lots of material quickly) in soft materials.

- If you step over by too large an amount, there are larger sideways forces on your tool and on your machine. This is usually not enough to be dangerous, but you might want to reduce depth per pass to compensate.

- Fusion 360 sets step-over to 0.9 times the tool diameter, which leaves a poor finish and can cause large forces in hard materials.

Summary

- Don't cut deeper than three times the tool diameter (under most conditions).

- Depth per pass should be set equal to the tool diameter.

- Step-over should be set to half the tool diameter.