Fadal VMC20 CNC Mill

Overview

Vertical machining center donated to Make Nashville by Jeremy Todd of United Machine & Tool. It is an older machine built in 1993, and features brushed DC servos rather than modern 3-phase brushless servos, however the technology is still robust!

Specifications

| Model | 904-20 |

|---|---|

| Serial | 9103079 |

| Voltage | 230VAC |

| Phase | 3 |

| Frequency | 60Hz |

| Full Load Amps | 25A |

Replacement Parts

Automatic Tool Changer

- #10-32x1/2" socket head caps screws with split washers secure the dog keys near the forks under the ATC carousel. 5/32" hex key required.

- 1/8"x1/2" roll pins for holding the steel forks into the ATC carousel.

- 3.34" OD 2.55" ID 0.056" thick plastic washers as bushings for the umbrella slide open door.

- 5/16-18x2-5/8" socket head caps crews for securing the geneva wheel to the ATC shaft drum.

- 3/8-16x1-1/2" hex head bolts for securing the aluminum bottom cap to the ATC shaft drum. 9/16" wrench/socket required.

- 14pcs ~2" OD ~1.0" ID spring washers both above and below the ATC shaft bearings.

- 1.54" OD 1" ID needle roller thrust bearings, 0.138" thick overall, partially due to 2pcs 0.030" thick washers.

Ballscrews

X axis

Ballscrew

- 32mm OD ballscrew, 0.2" lead, 1/8" balls.

- 25-5/8" ballscrew journal length

- ~1-1/16" or ~27mm diameter shoulder, 9.5mm or 0.375" long.

- 20mm diameter shaft for angular contact bearings, 29.2mm long (for pair of 15mm thick bearings)

- 3mm thread relief, 16.5mm diameter.

- 3/4"-16 threads, 16mm long including the 3mm relief (13mm of actual threads).

- 0.625" diameter shaft for lovejoy coupler, 25.2mm long. It has a 3/16" thick Woodruff key cutout.

- marked "9 M Y" and "18" on the floating end.

Ballnut

- 70.6mm OD flange, 12.7mm (1/2") thick.

- 5x 0.336" (8.5mm) clearance holes in a 2-5/16" diameter hex hole pattern (missing the hole that would interfere with the ball returns).

- 43.3mm OD cylindrical body.

- 37mm ID bore for wiper, ~5.6mm deep.

Angular contact bearing block

-

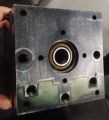

bearing block/servo mounting block to casting area (photo 1)

-

bearing block/servo mounting block to casting area (photo 2)

-

ballscrew side (oil seal removed)

-

lovejoy/motor side (retainer cap removed)

-

bearing retaining cap (inward side)

-

bearing retaining cap (outward side)

-

servo motor mount

Square bearing block:

- 1.75" diameter 0.25" deep lip for retaining angular contact bearing, and for the spring lip oil seal.

- 0.98" or 24.9mm thick block out of smooth black anodized aluminum.

Retaining cap:

- 15mm thick, ~2.98" or ~76.7mm OD

- ~52mm ID for press fitting angular contact bearing

- 1.75" ID ~3/16" or ~4.75mm thick lip to keep bearing from coming out of front face, as well as for press fitting the spring lip oil seal.

- 4x ~0.325" diameter 5/16" bolt clearance holes in a 2.5" diameter bolt hole pattern.

- held on by 4pcs 5/16"-18x1-1/4" hex bolts (1/2" wrench) and split lock washers.

- made out of smooth black anodized aluminum

Angular contact bearings

NSK 7304B G JAPAN

52mm OD, 20mm ID, 15mm thick

Oil seal:

NATIONAL 471692 USA

Apparently 1.125" shaft diameter, 1.756" OD, 0.250" thick.

Locknut

3/4"-16 threads, 28mm (?) wrench, 15mm thick, 26.9mm diameter, 9.3mm turned down region.

It is probably one of the following parts:

Buy Fadal Ballscrew Retainer Nut Small, BLS-0047 | ITSCNC.com

Buy Fadal Ballscrew Retainer Metric Screws, BLS-0049| ITSCNC.com

Woodruff key

#61 Woodruff, 3/16" x 5/8"

HDW-0382 - Genuine Fadal Hardware

Buy Fadal Woodruff Key #61 3/16" X 5/8", HDW-0382 | ITSCNC

Compatible replacements on McMaster-Carr:

Woodruff Key, 1018-1045 Carbon Steel, Key Number 61, 3/16" Wide | McMaster-Carr

High-Profile Woodruff Key, 1018-1045 Carbon Steel, Key Number 61, 3/16" Wide | McMaster-Carr

Servo Motors

DC Motors

X axis:

| Baldor DC Servomotor | ||

|---|---|---|

| CAT No | ITS731D002M8 | |

| Spec No. | 55P551Z119G1 | |

| Mfg No. | B1012060066 | |

| Torque, Stall | 38 LI Cont. | |

| Max. Speed | 3500 RPM | |

| Max. Voltage | 180 VDC | |

| Voltage Const. | KE = 36 V/kRPM | |

| Current Cont. | 15.1 A | |

| Current, Peak | 65 A | |

| Insulation | Class F 25°C Amb. | |

| Fort Smith, AR 72902 Made in U.S.A. | ||

Mounted using 4pcs 3/8" bolts, 9/16" wrench size, 1/2" long threads. There are also split lock washers.

Resolvers

Either a Advanced Micro Controls R11W-F10/7:

R11 Size 11 Brushless Resolvers

Advanced Micro Controls R11W-F10/7 Specification Sheet (Sheet # 940-2T440)

Or an API Harosyn 11BRW-300-F 1/6

Size 11/R11 Heavy Duty Brushless Resolvers | Dynapar

OEM parts:

Resolvers | Product Education | FadalCNC.com

PCB

Seems to be a Glentek GM4000-1058 board with the following over-temperature sensor:

Servo Motor Cables

The original X axis servo cable was a 1/2" watertight conduit containing smaller cables:

- braid shielded 2 conductor 14 AWG (105 strands) pretinned, internal jacket colors are red/black with gray outer jacket, ~0.325" jacket diameter

- green/yellow striped 14 AWG (41 strands) pretinned ground wire

- 0.1" outer jacket diameter, ~0.55" inner jacket diameter, 26 AWG or 25 AWG (7 strands) pretinned, braid shielded coaxial cable

- foil shielded (w/ drain wire) 4 conductor 22 AWG (7 strands) pretinned, internal jacket colors are red/black/white/green with gray outer jacket, 0.157" jacket diameter

- foil shielded (w/ drain wire) 2 conductor 22 AWG (7 strands) pretinned, internal jacket colors are red/black with gray outer jacket, ~0.130" jacket diameter

WIR-0090 | NXGEN Fadal Machine Parts

The cable has some coaxial "bullet" connectors:

TE 201143-1 (need to verify)

Which connect to the 1010 cards in the control cabinet

TE 50107-1 (need to verify)

wrong axis controller board on fadal machine?

Fadal 4th axis, plugged it in and the machine went down

The cable has contacts that need to be loaded into the following connector that goes into the backplane PCB near the bottom of the cabinet:

Which requires one of the following tools to extract the 0.093" (2.36mm) pins:

Molex 0011030006 (unsure)

It also has this connector for the resolver board inside the servo feedback area:

Servo Amplifiers

Brushed DC servo amplifiers made by Glentek. The nameplate reads:

Glentek El Segundo, CA. Model: GA4568-4E-1 Serial: 3090 HF 3Ø

Documentation is still available:

GA4567EPC / GA4568EPB Operation and Service Manual

From Glentek's website:

Relay Board

The board has marked on it's silkscreen:

1100-1B Fadal PF-B94V-0

1100-1B RELAY DISTRIBUTION BOARD | FadalCNC.com

The board seems to have 7 solid state relays, two bypassed outputs (no isolation), and two mechanical relay outputs.

CPU Board

Fadal 1400-2A

Software Module

Fadal VMC V91.1A-2 2091

Online Resources

- Manufacturer's web site.

- Manufacturer documentation.

- Manuals. The "2016" is the closest match (the updated version of this machine).

- How to set up serial communications. It wants 7e1, xon/xoff flow control, and the file must start and end with a % sign.