Carve King CNC Router: Difference between revisions

(Added "software issues" section (getting the post-processor and the controller to play nicely with each other).) |

(→Feeds and Speeds: Added ABS faceplate info.) |

||

| Line 38: | Line 38: | ||

| Delrin || 1/8" 2-flute end mill || 3 mm || 1.5 mm || 6 || 500 mm/min || 300 mm/min || 200 mm/min | | Delrin || 1/8" 2-flute end mill || 3 mm || 1.5 mm || 6 || 500 mm/min || 300 mm/min || 200 mm/min | ||

| CJT feb 2020 || Up to 1000 mm/min works fine. | | CJT feb 2020 || Up to 1000 mm/min works fine. | ||

|- | |||

| ABS || 1/8" 2-flute end mill || 3mm || n/a || 6 || 750 mm/min || 250 mm/min || 250 mm/min | |||

| CJT july 2020 || Making cutouts in faceplates 1/8" thick without support. Keep plunge rates 250 or lower to reduce deflection. | |||

|- | |||

| ABS || 90 degree v-bit || 0.8mm || n/a || 6 || 750 mm/min || 250 mm/min || 250 mm/min | |||

| CJT july 2020 || Engraving lettering in faceplates. Keep plunge rates 250 or lower to reduce deflection. | |||

|} | |} | ||

Revision as of 15:45, 16 July 2020

|

This equipment requires training. Either it's tricky to use, or it's someone's personal equipment, or it's easy to make expensive mistakes with. Training courses happen regularly, and are scheduled on EventBrite. |

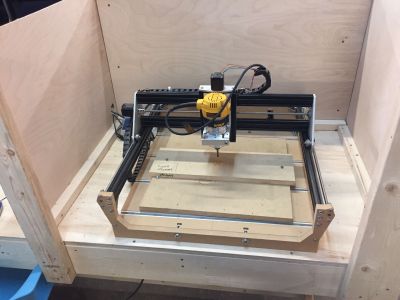

The Carve King CNC router is on loan to the shop from Keech, starting in the fall of 2019. It is a "Carve King" by MillRight.

Overview

- This router is not sturdy; the frame will deflect when machining hard materials or at aggressive feed rates. Please do not use metal with this machine (just wood, plastic, foam, and other soft materials).

- This machine uses a hardware-store router. Speed "6" on the router dial is 16,000 RPM. There is no computer control of spindle speed.

- The router has a 1/4" collet. A 1/8" collet is available, but we don't have one; for now, use end mills and router bits with a 1/4" shank with this machine. You can get 1/4" and 1/8" end mills with 1/4" shanks.

- Table area is about 20" by 20". The maximum practical workpiece size is about 16" by 16" (perhaps slightly larger). Nominal vertical travel is about 5", but the actual maximum workpiece size is about 2" (1" for the spoilboard, 2" for the workpiece, 2" for clearance plus the end mill itself if entering the workpiece from the top).

- The upper cable guard will sometimes come loose and touch the X axis limit switch, causing the machine to stop. If the machine stops in the middle of the table, check to see if that happened.

Feeds and Speeds

The following settings have produced good results. If you try something new and it works, add entries at the bottom of the table.

Unless otherwise indicated, "end mill" means spiral up-cutting flat-bottomed end mill.

| Material | Tool | Depth Per Pass | Step-over | Router Dial | Feed Rate | Ramp Rate | Plunge Rate | User / Date | Notes |

|---|---|---|---|---|---|---|---|---|---|

| plywood | 1/4" 2-flute end mill | 3 mm | 90% | "6" | 500 mm/min | 100 mm/min | 100 mm/min | CJT fall 2019 | Decent results. |

| pink styrofoam | 1/4" 2-flute end mill | 15 mm | n/a | "6" | 2000 mm/min | 1000 mm/min | 500 mm/min | CJT fall 2019 | Vacuum constantly to avoid chip welding. |

| wood (maple?) | 1/4" 2-flute end mill (straight-flute) | 6 mm | 3 mm | "4" | 150 mm/min | 100 mm/min | 50 mm/min | CJT feb 2020 | Need straight-flute for decent finish. 300 mm/min ok for roughing. Can go faster along grain, but cross-grain will chatter. |

| HDPE | 1/8" 2-flute end mill | 3 mm | 1.5 mm | 6 | 500 mm/min | 300 mm/min | 200 mm/min | CJT feb 2020 | Up to 1000 mm/min works fine. Slower than 500 leaves crud on top edges. |

| Delrin | 1/8" 2-flute end mill | 3 mm | 1.5 mm | 6 | 500 mm/min | 300 mm/min | 200 mm/min | CJT feb 2020 | Up to 1000 mm/min works fine. |

| ABS | 1/8" 2-flute end mill | 3mm | n/a | 6 | 750 mm/min | 250 mm/min | 250 mm/min | CJT july 2020 | Making cutouts in faceplates 1/8" thick without support. Keep plunge rates 250 or lower to reduce deflection. |

| ABS | 90 degree v-bit | 0.8mm | n/a | 6 | 750 mm/min | 250 mm/min | 250 mm/min | CJT july 2020 | Engraving lettering in faceplates. Keep plunge rates 250 or lower to reduce deflection. |

Software Issues

Fusion's post-processor for GRBL will sometimes generate code that the Carve King doesn't like. To prevent this, edit the following settings in the lower right part of the post-processing dialog:

- "G28 safe retracts" set to "no".

- "Output M6" set to "no".

- "Output tool number" to "no".

You may need to make additional changes to suppress "G18" and "G19" codes (working-plane changes):

- When setting up contouring operations, go to the "linking" tab and turn off "lead-in" and "lead-out". (This will leave rough spots on the workpiece due to plunging right next to the cut instead of coming in from the side, so only do it if you have to.)

Hardware and Software Specs

- The hardware-store router is a DeWalt DWP 611.

- The machine's controller is FIXME: specific software package running on FIXME: specific hardware board. It speaks GRBL.

- The controller really doesn't like certain commands; in particular, it fails on tool changes (M6), operating plane selection (G17, G18, G19), and various other things (such as the "G28 G91 Z0" line Fusion likes to put in at the top). Edit the post-processed G-code to remove all instances of these if you're getting errors running your code.

- Use Universal G-Code Sender to talk to the controller.

- FIXME: Stepper motor and motor driver information goes here. The vendor page has it.